THE MANUFACTURE OF MILK POWDER

4 August 2020

THE MANUFACTURE OF MILK POWDER

Drying means that the water in a liquid product—in this case milk—is removed, so that the product acquires a solid form. The water content of milk powder ranges between 2.5% and 5%, and no microbial growth occurs at such a low water content. Drying extends the shelf life of the milk, simultaneously reducing its weight and volume. This reduces the cost of transporting and storing the product.

Preheating conditions are used to a large extent to control the functional properties of

the powder. A number of changes occur in milk during preheating: whey protein denaturation, association of denatured whey proteins with the casein micelle, transfer of soluble calcium and phosphate to the colloidal phase, destruction of bacteria, and inactivation of enzymes.

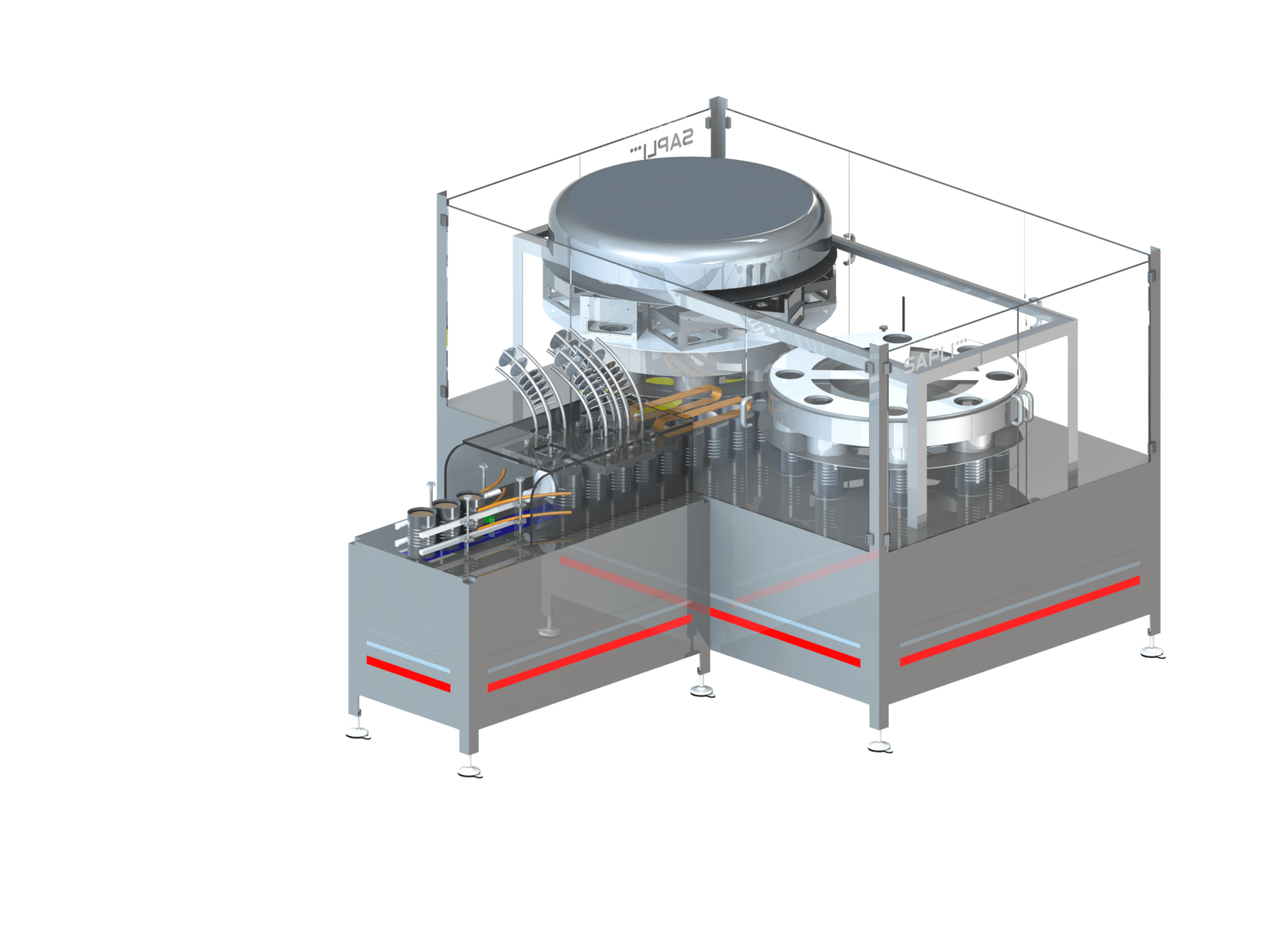

The manufacture of milk powder involves a series of continuous or semicontinuous steps, such as milk standardization, thermal treatment, evaporation, spray drying, and : uidized bed drying, each of which has associated process variables that affect the effciency of the process and the quality of the product.

The manufacturing process for skim milk powder (SMP) involves heating the skim milk (known as preheating), concentrating the skim milk solids by evaporation to 45–50% total solids, heating the skim milk concentrate, and then spray-drying the milk concentrate to produce a powder. Depending on the intensity of the heat treatment, milk powder is classifed into categories related to the temperature–time combinations the skim milk has been exposed to prior to evaporation and drying. High temperature denatures whey proteins, the percentage denatured increasing with the intensity of the heat treatment. The degree of denaturation is normally expressed by the whey protein nitrogen index (WPNI) as milligrams of undenatured whey protein (u.w-p) per gram of powder. SMP is classifed into the following three types based on the WPNI, which is correlated to the spray-drying conditions: low-heat powder (70°C/15 sec, WPNI >6.0 mg g–1 u.w-p), medium-heat powder (85°C/20 sec, WPNI 5–6.0 mg g–1 u.w-p), and high-heat (~135°C/30 sec, WPNI <1.4 0 mg g–1 u.w-p).

In the manufacture of Whole Milk Powders (WMP), milk is subjected to a range of processes such as agitation, pumping, heating, concentration, homogenization, and spray drying. These processing treatments cause a number of physical and chemical interactions of the milk components.