METAL TIN CAN SEAMER WITH VACUUM AND NITROGEN

METAL TIN CAN SEAMER IN MODIFIED ATMOSPHERE

Improve quality and extend shelf life of milk powder, vitaminic products and infant baby formula

Role and importance of packaging

In the process of storage and handling, milk powder and infant formula milk powder will have some unfavorable effects on nutrients in varying degrees. Packaging separates infant formula from the surrounding environment, thereby eliminating the effects of environmental factors (oxygen, humidity, light, temperature and microorganisms) on the milk powder, and avoiding physical and chemical changes in the nutrient contents. To ensure that the milk powder is in product circulation links with stable quality, extend shelf-life and storage-life of milk powder.

Stable and beautiful packaging can increase the value of infant milk powder to consumers with a sense of hygiene, nutrition, taste and sense of security. Thereby enhancing the value of the milk powder, effectively promote the sale of milk powder.

Second, the role of storage of nitrogen packaging

Powdered milk, especially baby food, is a highly sensitive product. To extend shelf life, it is important to displace oxygen from the Package by evacuating air and filling with clean nitrogen with low residual oxygen. Nitrogen, accounting for 78% of the volume of air, exists in air as an elemental substance and is inexhaustible. It is a colorless, non-toxic and tasteless inert gas.

The cans are mostly filled with nitrogen when packaging, segregated the milk powder direct contact from the oxygen in air, to prevent the oxygen and infant milk powder direct contact caused by with oxidation, fading, corruption and a variety of mold, bacteria, thus ensuring the freshness of infant milk powder, extending the storage period of infant milk powder. Therefore, the level of residual oxygen in the cans is essential, to prevent oxidative deterioration of milk powder due to excessive levels of oxygen.

Revolutionary solution

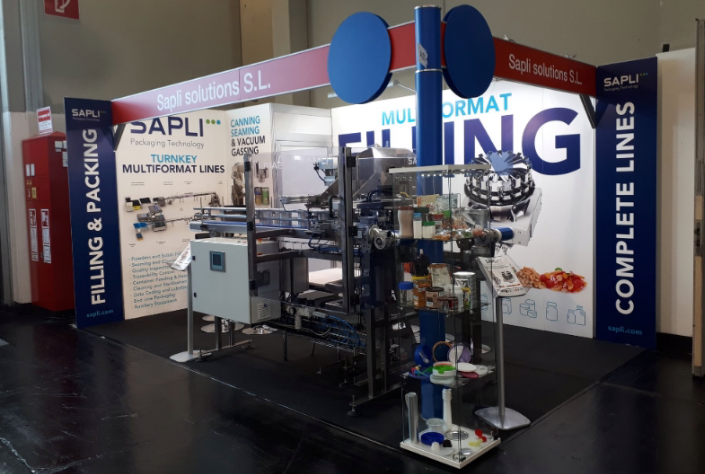

Seamer with the best vacuum and gassing system in the market. An MAP canning system especially for powdered products with the highest level of quality for final consumer and an extended shelf-life of the product for the manufacturer. Suitable for any kind of powdered or grain product that require a lox level of oxygen and the best quality method.

Sapli, offers the unique on the market and patented solution for modified atmosphere (MAP) - highly-efficient cans seaming system, developed specially for maximum reduction of vacuum gassing and sealing cycle and achieving reduced and optimal level of oxygen inside the can (around 0.5-1%).

Sapli substitutes the existing air in the can and in between the powder particles for N2 and CO2 with the best solution existing in the market.

Sapli also has added-value solutions to most of the production steps and they all result into one or several of the below mentioned advantages:

- Best quality packaging

- Low footprint used

- Low Nitrogen consumption

- Best return of investment