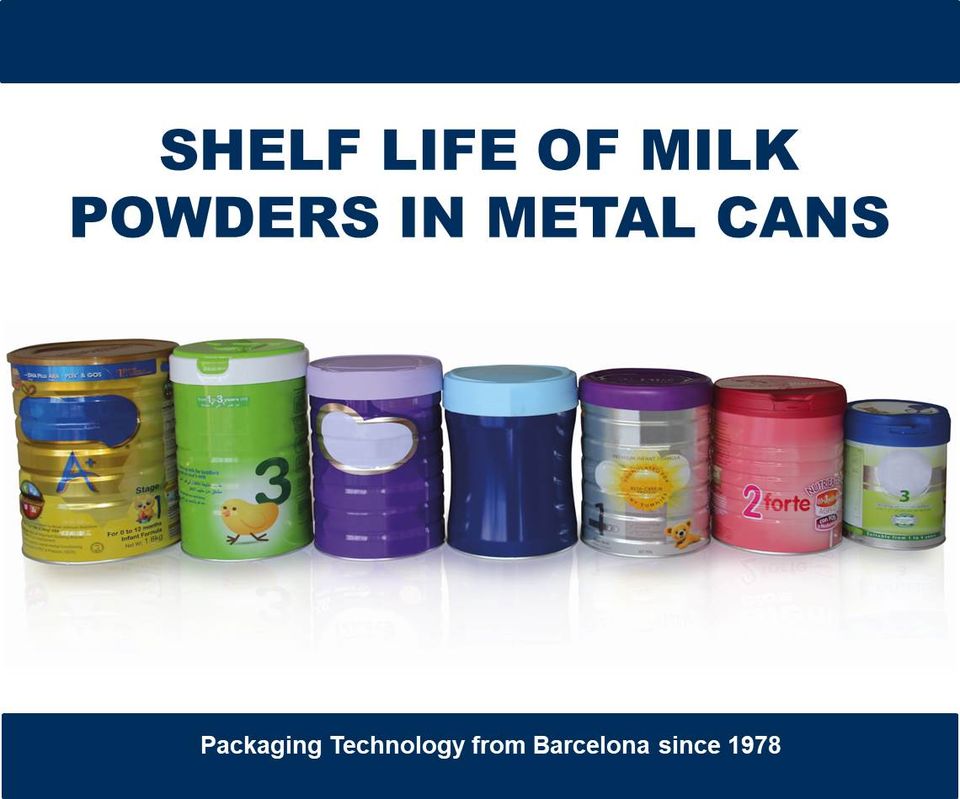

SHELF LIFE OF MILK POWDERS IN METAL CANS

10 March 2020

SHELF LIFE OF MILK POWDERS IN METAL CANS

Packaging milk powder in metal cans has been highly popular for a long time, particularly for retail packaging. For example, cans are commercially available with capacities of 400, 900, 1800, and 2500 g. The main reason for using metal cans is their excellent physical strength, durability, absolute barrier properties to moisture, O2, and light, absence of flavor, and rigidity.

Because bare steel is susceptible to corrosion, it is commonly electrolytically coated with a very thin layer of tin; in addition, an organic lacquer is applied to further protect the metal from corrosion and avoid metal–food contact. The milk powder steel can is commonly cylindrically shaped and may feature a reclosable (tight fit) lid. In the standard version the can features a cylindrical body with “can ends” on both ends. The can body is welded longitudinally, and the can ends are seamed onto the can body. To obtain appropriate closure (i.e., to maintain the integrity of the pack) an elastomeric compound is included in the end seam. In cans with a reclosable lid it is common to seal the underside of the can end with an aluminum foil laminate to ensure integrity during storage and distribution.

Milk powder has a long shelf life when packed in metal cans due to their excellent barrier properties. The exchange of moisture and O2 and the influx of light are not possible. Powders with a higher fat content are more susceptible to oxidation, and most powders are susceptible to deteriorative effects such as lumping and caking from moisture ingress. With adequately constructed cans, a shelf life in excess of 5 years is realistic, particularly when FMP products have been gas-flushed with N2 to minimize the amount of available O2. However, national food safety authorities often adopt a conservative approach by reducing the nominated shelf life. Nonfat dry milk (NDM) and powdered whey beverages are available at the retail level in the United States and many other countries packaged in no. 10 cans (157 × 178 mm with a capacity of 3108 mL) in a reduced-O2 atmosphere to prolong shelf life (up to 54 months). In the 10 US brands tested, wide variation existed in headspace O2, can seam quality, sensory quality, and vitamin A (with 6 of 10 brands entirely lacking the vitamin). The aw of the brands ranged from 0.14 to 0.28 (a typical range), corresponding to 3–5% moisture content. The brand that scored highest in overall acceptability had an average headspace O2 of 7% and poor can seams, calling into question the ability of the package to maintain product quality over an extended storage time.

Source: Taylor and Francis Group, LLC 2010